Adding a truck sounds like a sign of success until it backfires. One local plumber learned this the hard way when his shiny new van became a monthly money pit. So, when’s the right time to grow your fleet? Let’s break it down.

Running a plumbing business, or any contractor business, is not easy. And growing it. Well, that’s a whole second set of problems.

Most contractors have a dream of getting out of the field and into the office. They dream of having a busy schedule with qualified technicians doing the work, while they count their profits.

But, how do you get your business to this point?

It’s an age-old problem for many blue-collar business owners.

Some, like Fred, are quick to hire thinking that the more trucks they have on the road, the more money they can generate.

But, carefully planning growth is critical to your business’s success. If you jump the gun too early, it could cost you profits, or even your business.

Fred’s story is a common one. He was doing $650,000 in revenue quite consistently between himself and another technician. However, he was constantly frustrated, trying to find a way to work himself out of the field.

“I need to find ways to grow.”

“I need to hire more technicians to do this work, so I can focus on the business.”

These were the common conversations he would have with his wife over the dinner table.

Then…

A big Winter storm hit his area (a place not typically known for harsh Winter weather). Pipes were freezing and Fred’s phones were ringing off the hook.

“Finally,” he thought. He posted some ads on Indeed and started looking for another tech.

He quickly found a new plumbing technician and hired him right away. The new tech helped Fred get through the mess of the Winter storm. But, when the weather broke and the calls slowed down, his business took a turn for the worse.

Despite the fact that Fred did $800,000 in revenue that year, he did not have a solid process in place for staying busy in order to keep the new technician paid. In fact, he made less profit on $800,000 than he was making on $650,000!

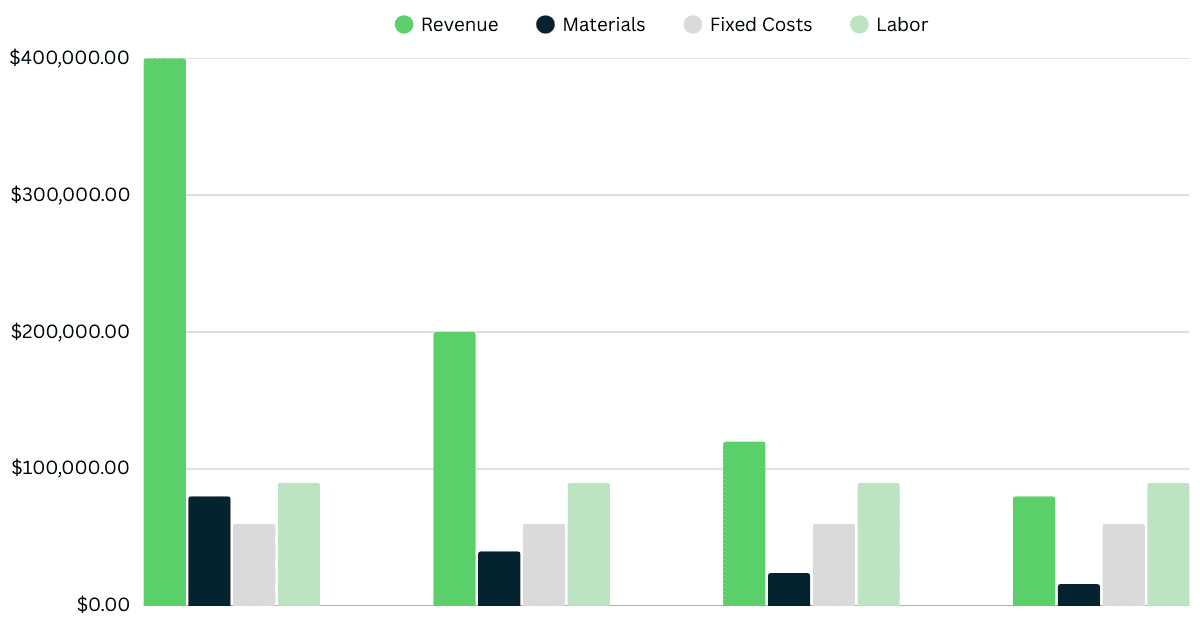

His year looked something like this:

| Period | Revenue | Materials | Fixed Costs | Labor | Profit |

| Q1 | $400K | $80K | $60K | $90K | $170K |

| Q2 | $200K | $40K | $60K | $90K | $10K |

| Q3 | $120K | $24K | $60K | $90K | ($54K) |

| Q4 | $80K | $16K | $60K | $90K | ($86K) |

| Total | $800K | $160K | $240K | $360K | $40K |

As labor costs increased due to the new hire, and without the sustained revenue to cover those costs, this plumber only profited $40,000 on $800,000.

This issue could have been avoided had he followed a simple formula for adding new trucks.

Follow the guide below to learn how to implement this formula in your business…

Optimize Your Current Techs

Before you make the mistake of hiring a new technician, it’s important to evaluate your current technicians’ workloads.

Are they as busy as you think they are?

Can their schedules be optimized for better productivity?

Do you have a scheduling software in place that can help you optimize productivity?

It’s best to try and maximize your current technicians to the best of your ability. Try to stretch their schedules as far as they can go without adding more cost by hiring new team members. It’s often the case that despite technicians being “busy” they are not productive.

Here are some tips for improving productivity:

- Route Optimization: Be sure that your current technicians are working in specific territories and not driving long distances between jobs. This can help them do more on any given workday.

- Strategic Job Assignments: Tracking time-on-job by technician will help you gather data on who gets what done the fastest. If Tech A is faster at certain job types, you should be assigning that work to him.

- Setting Customer Expectations: Nothing is worse than wasting travel time to a customer who does not move forward with the job. Use this script to train your phone answerers on how to set the right expectations with customers before the job is scheduled.

After you’ve confirmed that your current technicians are “maxed out”, it’s time to start thinking about growing the size of your fleet. Follow these next steps to dive into the financial details…

The Real Cost of a New Truck

Gross profit is a measure of your revenue less any cost of goods. Material costs and labor performed on each job should be treated as cost of goods sold (COGS) from an accounting perspective, in addition to any marketing dollars spent to acquire new customers. By tracking this financial data properly, you should be able to get an idea of your overall gross profit margin.

A healthy plumbing business should have 60% gross profit margins for all service work.

Here is a simple way to determine gross profit margin:

(Revenue from last year) – (COGS from last year) / (Revenue from last year)

($1,000,000) – ($400,000) / ($1,000,000) = 60%

In Fred’s case, his gross profit margin was much less. Let’s do the math using the numbers in the chart above.

($800,000) – ($520,000) / ($800,000) = 35%

No wonder he didn’t make any profit.

Holding true to a 60% gross profit margin when hiring new technicians is your safest bet for remaining profitable. Let’s look at a few examples to illustrate this:

Scenario A – Two Technicians

| Revenue (100%) | Materials (15%) | Labor (25%) | Gross Profit (60%) |

| $1,000,000 | $150,000 | $250,000 | $600,000 |

In the above scenario, each of the two technicians represents 12.5% of total revenue and the business is running a 60% gross profit margin. In order to make room for an additional technician, revenue needs to increase.

Scenario B – Organic Revenue Growth – Two Technicians

| Revenue (100%) | Materials (15%) | Labor (20%) | Gross Profit (65%) |

| $1,250,000 | $187,000 | $250,000 | $812,500 |

In Scenario B, by increasing revenue and maintaining labor costs (two technicians), our labor costs now represent 20% of revenue, with each technician accounting for 10%. Your gross profit margins increased to 65% and it’s time to consider hiring a new technician.

Scenario C – Three Technicians

| Revenue (100%) | Materials (15%) | Labor (30%) | Gross Profit (55%) |

| $1,250,000 | $187,000 | $375,000 | $687,500 |

Hiring a third tech brings the total labor costs to 30% of revenue, reducing our Gross Profit margin to 55%. This is still within a healthy range and can be recouped through additional revenue growth.

What about marketing and advertising?

Great question!

Marketing dollars can help drive revenue. These dollars are accounted for in COGS and a detailed analysis has to be considered to understand if those dollars are actually driving profits. Using tools like shwego™ can help you attribute revenue to marketing channels to understand their impact on profits.

With that being said, it’s also prudent to consider a marketing budget each time you hire a new technician.

In the example above, simply hiring a new technician after achieving $1,250,000 in revenue without a plan for sustained growth would be foolish. In order to maintain healthy gross profit margins, it’s important to continue to grow revenue after hiring a new technician.

Now, not all marketing dollars are created equal. There are several factors to consider, such as average customer acquisition cost and return on ad spend (ROAS). Once you have a handle on the impact of your marketing dollars, you should create a budget and take those costs into account.

Here is what it might look like:

| Revenue (100%) | Marketing (5%) | Materials (15%) | Labor (25%) | Gross Profit (55%) |

| $1,500,000 | $75,000 | $225,000 | $375,000 | $825,000 |

In this scenario, we have hired a new technician (total count is now three), and we budgeted $75,000 for marketing. These marketing dollars are projected to generate additional revenue that can help sustain revenue levels.

In the above scenario, your gross profit margin is still 55%. Your revenues still need to grow to $1,687,500 in order to achieve your 60% margin, but you are off to a good start.

Don’t Be Like Fred

Fred did not think about his numbers before hiring his new technician. He did what we call “revenue math”. His revenue was growing and he defaulted to hiring a new employee, without digging into his gross profit margins. Here is a rough cost guide that you can use to keep your hand on the financial pulse of your service contractor business. You should be evaluating these costs percentages on a monthly basis and doing everything within your power to achieve them:

| Cost Item | Percentage of Revenue |

| Revenue | 100% |

| COGS | 40% |

| (Materials ~15%) | |

| (Labor ~20%) | |

| (Marketing/Advertising ~5%) | |

| Fixed Costs | 30% |

| (Rent & Utilities) | |

| (Truck Payments) | |

| (Insurance) | |

| (Software) | |

| Net Profit | 30% |

Key Take-Aways

- Make sure your existing technicians are being fully productive

- Only hire new technicians when current techs are maxed out

- Understand your costs

- Run realistic revenue projections

- Be sure that you can cover your new technician’s salary with revenue from marketing or organic growth

Need help staying organized so you can grow smart, not just fast?

shwego™ was built to help service contractors like you manage jobs, track performance, and grow with confidence. Book a free demo to see how it works.

Until next time,

-Sam